Reshaping Our World's Future with Microfabrication Excellence

Tekscend Photomask goes beyond expectations every time, everywhere!

NEWSROOM

-

Information

InformationTekscend Photomask Expands Production Capacity in Europe with Strategic Photomask Writing Investment

-

Information

InformationTekscend Photomask Japan Launches its new Nanoimprint Lithography line (NIL) Capabilities

-

Information

InformationTekscend Photomask Establishes New MVV

-

Information

InformationTekscend Photomask Signs Partnership Agreement with Shiga Lakes

About Tekscend Photomask

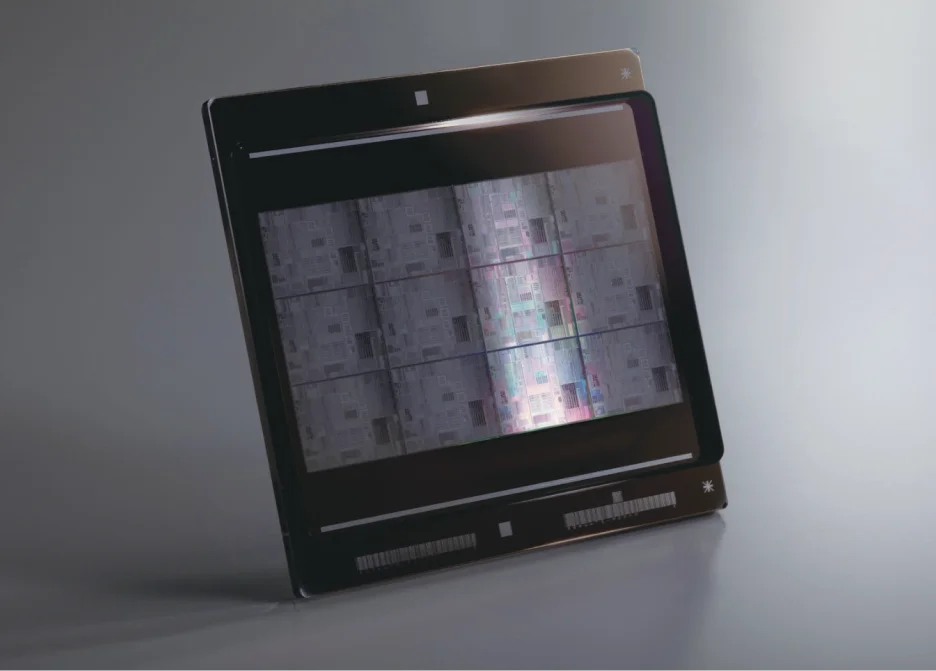

Tekscend Photomask is the world's premier provider of semiconductor photomasks. Headquartered in Tokyo, Japan, Tekscend Photomask leverages its worldwide customer service network and eight manufacturing sites in key geographic locations to provide the world's most advanced lithography technology. Tekscend Photomask is also expanding into nanoimprint molds and other nanofabricated products.